Molded Grills

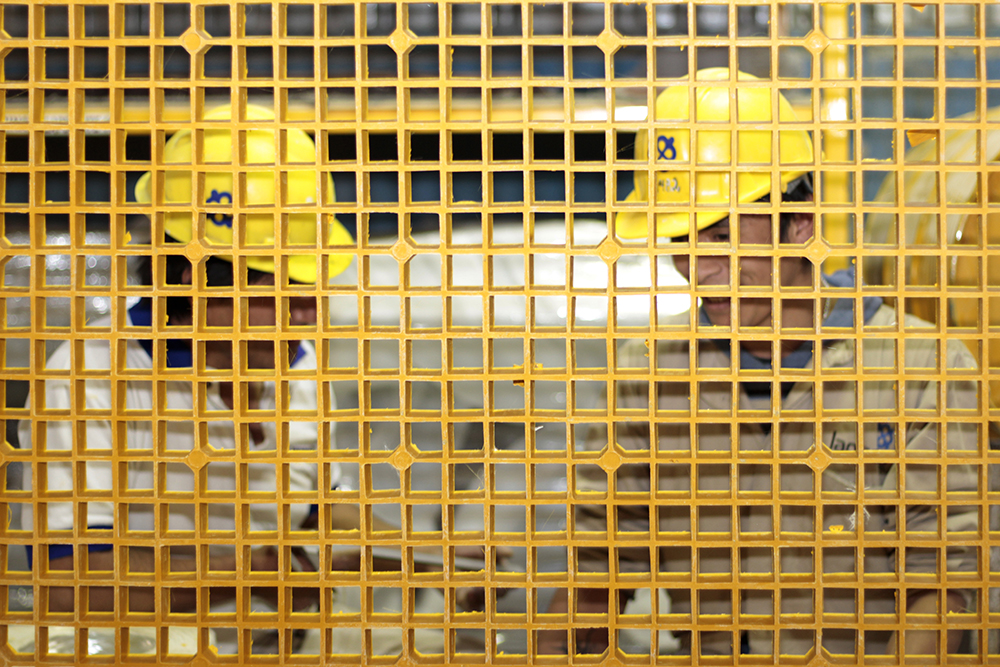

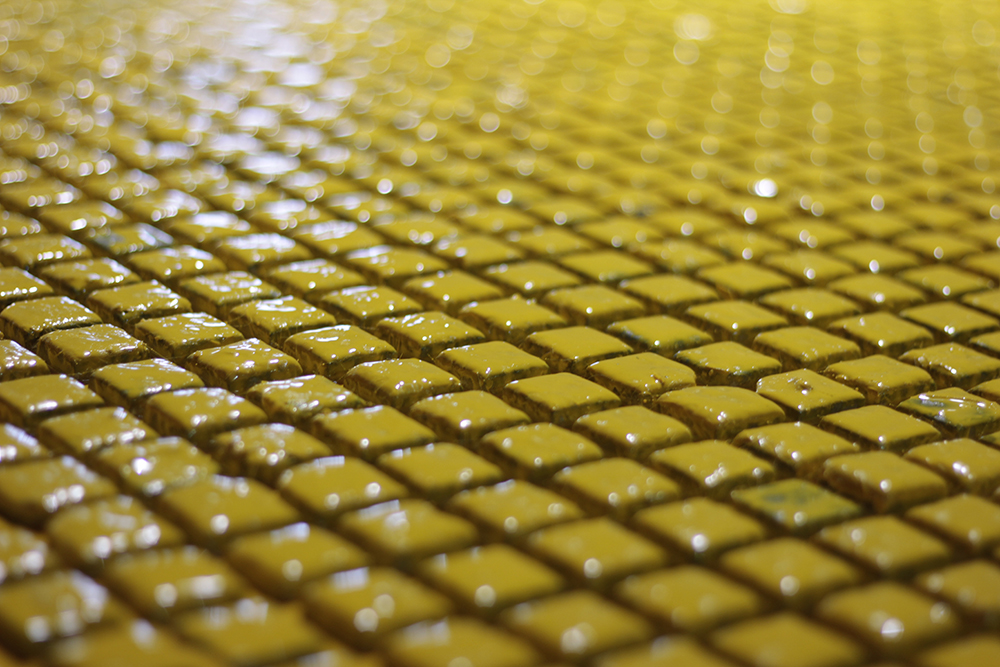

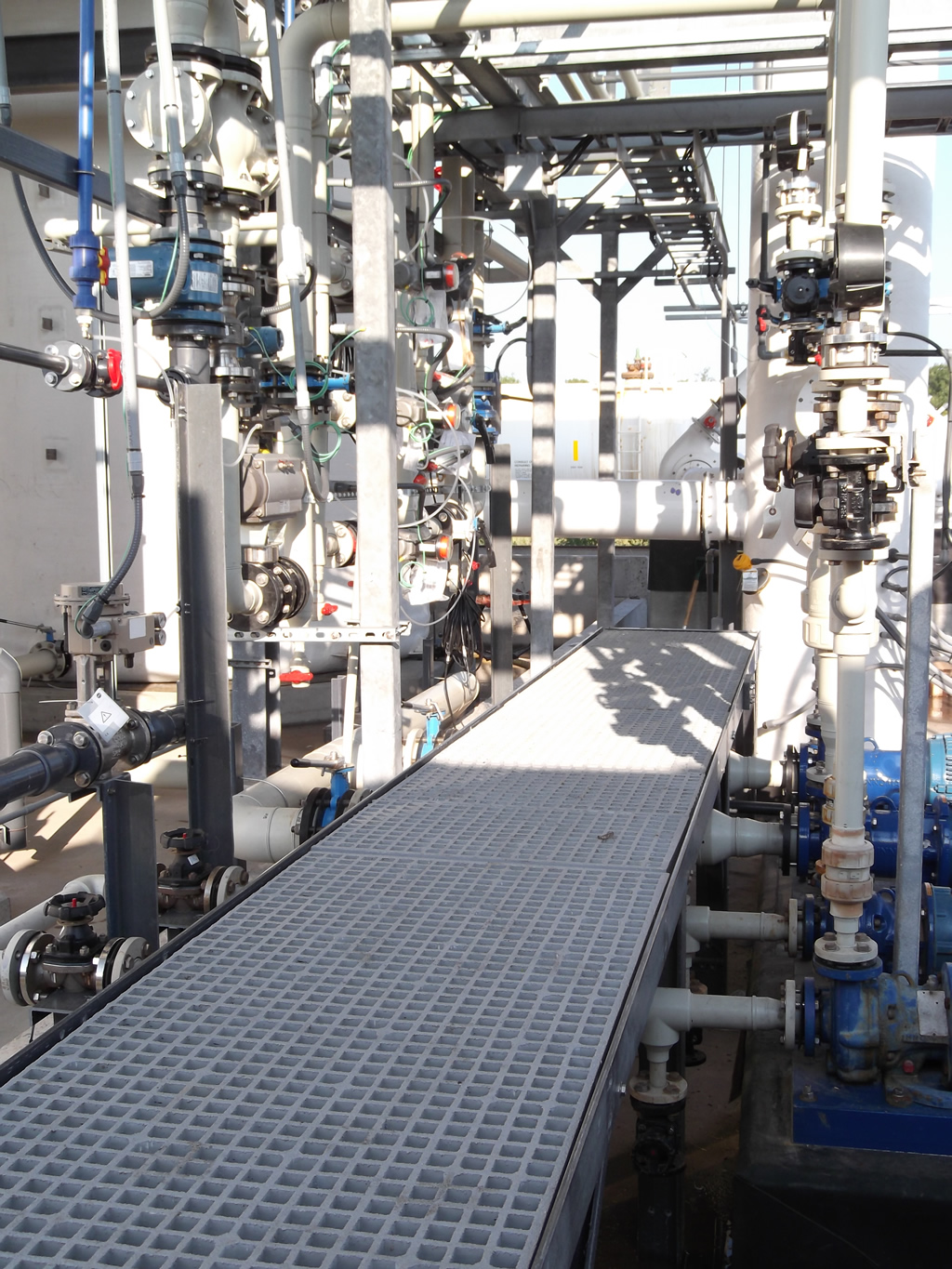

• Description: Fiberglass grills manufactured by a molding process are construction elements which can be employed as a measure of security for workers and as an option instead of steel and aluminum materials, with the advantage of being light-weight. They are highly recommended for corrosive environments, with strong panels that last for years even under extreme conditions.

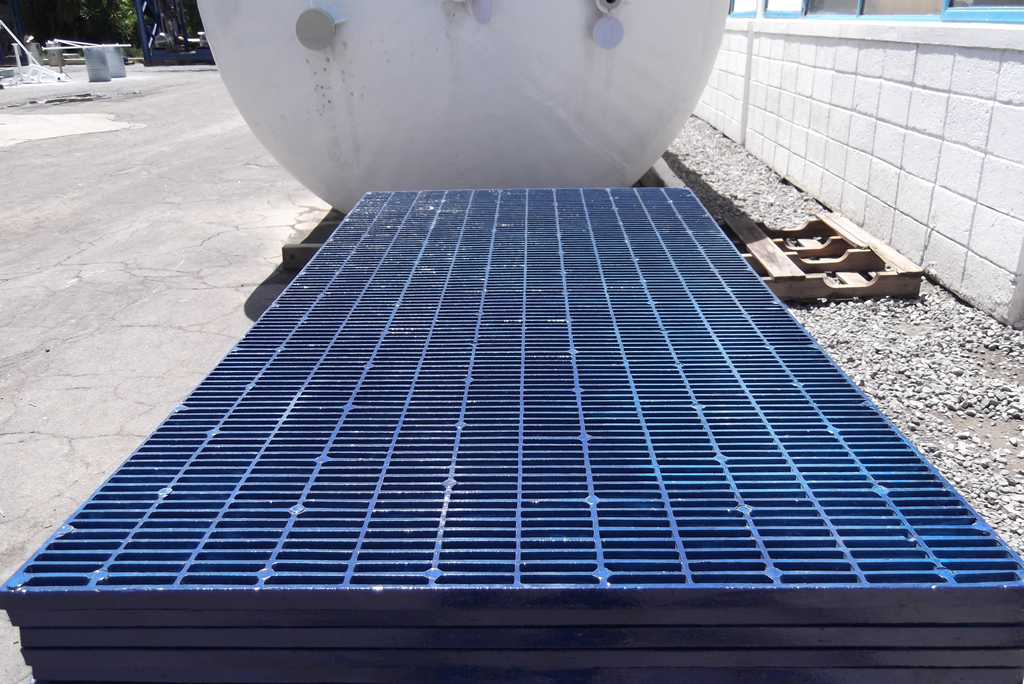

• Design ranges: Lapsolite offers the following 4 alternatives designed for different environments and applications, where each one contains as standard a UV rays inhibitor and are flame resistant according to the ASTM E84 norm.

• TYPE OF RESIN + TYPE OF MANUFACTURING + MESH TYPE + CANT + COLOR

|

Resin type |

Type of manufacturing |

Type of mesh |

Quantity |

Color |

|

LAP1: Bisfenolica |

M: molded |

C: square |

1 " |

C1: Blue |

|

LAP3: Isophthalic |

|

R: Rectangular |

1 ¼ " |

C2: Green |

|

LAP4: Orthophthalic |

|

|

1 ½ " |

C3: yellow |

|

LAP8: Resin vinyl ester |

|

|

1 ¾ " |

C $: grey |

Accessories

We also offer: rungs for ladders, attachment clips, sealing kits.

• Applications: Floors, platforms, ramps, storage areas, assembly lines, areas to cover large clearings, etc.

• Benefits:

a. Strong mechanical resistance.

b. Strong resistance to corrosion.

c. Low electrical and thermal conductivity.

d. Impact-resistant.

e. Non-skid surface.

f. Easy to assemble due to its low weight, which allows for minimal waste of a molded fiberglass grate vs metal grate

g. Low maintenance.

ENGLISH

ENGLISH